Your location:Home>About>Technical Support

Your location:Home>About>Technical SupportTraditional guide plate is made by acrylic or PS plate after cutting, polishing, screen printing light network, cooperate with the paste made of reflective film, its efficiency and uniformity of the light depends entirely on screen printing process control and material selection, adhesion of any branch, dust seal, ink deployment will lead to bright spots, dark space, such as uneven phenomenon, consistency is very difficult to control and brightness ascension has a bottleneck.

Free guide plate don't need to screen printing, screen printing microstructure is a kind of different from traditional network guide plate differential substructure guide plate, the upper and lower surfaces are differential substructure, within the light on the microstructure of light guide plate Angle of total reflection and the change from positive export of light guide plate, because it is directly by PS or PMMA material moulding and extrusion, without after treatment, the consistency of product and yield of 100%, due to the light in the inside total reflection of light guide plate, the rate of light guide plate is higher than traditional branch.

Structure and principle

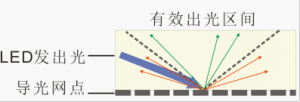

Screen printing guide plate

As shown, light guide plate inside the way forward is similar as in the following table tennis between wave forward, so we can understand the traditional outlets light guide plate principle is derived as shown in the figure below:

Guide plate

Due to the LED light is met in a scattering light node occurs when no rule and some escape from the smooth surface of light guide plate, as shown in figure only green light can escape out of the guide plate, the red light continued within the guide plate spread unceasingly, few behind branches diffuse from the positive run of light guide plate, most is in the process of transmission loss. From this we can understand the traditional points the way out of the light transmitting rate inherent inefficiencies and bottlenecks.

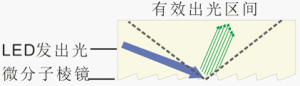

There is no silk screen luminance of light guide plate

Shown above for micro molecular light principle of light guide plate, and we know the principle of conventional led lens is the led light on the lens cone wall in full launch the almost zero waste discharged from the front of the lens, so the efficiency of the light for the traditional lens depends on its conical wall design and mold processing. Aia optical differential substructure guide plate is developed by using the principle of traditional LED lens, set in the bottom of the guide plate microstructure of particular Angle, when the LED of the incident light touching the microstructure surface happens when the full launch of a specific Angle, the direction of the reflected light is controlled by the microstructure perspective to all in the escape from the front of light guide plate area effectively, so as to avoid the light guide plate in the internal loss, improve the rate of the light.

Uniformity control and made

Differential substructure distribution of light guide plate can be according to the size, shape, density and location and adjustment, through the corresponding high precision optical mold core design uniformity of light yield and to achieve the optimum.