Your location:Home>About>Technical Support

Your location:Home>About>Technical SupportPMMA diffuser plate profile

PMMA diffuser plate, also called (polymethyl methacrylate, alias, acrylic, the strength, organic glass), is a kind of material with a nature of light diffusivity, is PS (polystyrene), PC (polycarbonate), PP (polypropylene) material such as diffusion plate category a, with a high degree of fog, high light transmittance, high diffusivity optical characteristics, such as plastic plate, can effectively convert point or line light source into soft, uniform surface light source, in the premise of good light transmittance, good light source bitmap shelter at the same time, the solution to the secondary light distribution of LED lamps and lanterns product is ideal optical material, is the best LED lighting products diffusion of light materials.

PMMA diffusion plate production background

In LED lighting lamps and lanterns gradually accepted by the market, on LED lamps and lanterns mask has been plagued by the lamp manufacturer, it is necessary to have high transmittance as the premise. At the same time, but also to achieve light sources has a light diffusion rate and good concealment, improve the lighting effect and the dazzling LED light source into the soft, healthy light source is the direction of R & D personnel are working on. Glass used to do the first light, but not broken glass, and the proliferation of light is not very good, it is difficult to meet the requirements of lighting. Later, gradually developed into the use of resin instead of glass, but if only use transparent resin to do the shade, although the transmittance is high, the basic can reach more than 90%, but the proliferation of light effect is not ideal, the hidden light source is poor. White resin, the presence of light transmittance is too low, a serious impact on the LED lighting. Such as with added milk white pigment, matte surface auxiliary means, so although the solution of the light shielding problems. However, there are also low transmittance, serious impact on the effect of light on the LED lighting, the diffusion mask has been plagued in light transmittance and light shielding of such a contradictory problems. Also in this context, the acrylic (PMMA), PS, PC plastic sheet material diffusion came into being.

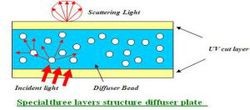

PMMA diffusion plate principle

Diffusion plate by chemical or physical means, use light in acts on the way encountered two different refractive index of the medium, refraction, reflection and scattering of physical imagination, by in the PMMA substrate based added inorganic or organic light diffusion agent, or through the substrate surface micro structure array arrangement of artificial adjustment of the light, the light in different directions of refraction, reflection and scattering, thus changing the optical path of travel, disperse color in order to produce the effect of optical diffusion in charge of the incident light.

Schematic diagram of diffusion plate:

1, the traditional diffusion board

The traditional PMMA diffuser plate is mainly in the PMMA substrate added chemical particles as scattering particles, so that the light refraction, reflection and scattering in the medium when passing through the scattering layer continuously in the two refraction rate different. In order to produce the effect of optical diffusion. In this way, it is inevitable that the diffusion of particles on the absorption of light, resulting in low utilization of light energy.

Frequently added chemical particles include: organic light diffusing agent inorganic light diffusion agent mixing uniformity.

2, a new type of micro structure diffusion plate

New micro structure of PMMA diffuser plate is through the surface micro structure array arrangement, the light reflection in different directions by, to change the light travel route, realizes that incident light is fully loose color, achieve more soft, uniform irradiation effect. Common micro special structures include the following:

A, V type groove array

B, U type convex slot array

C, Pyramid array

D, ring array

E, micro lens array

Micro structure of acrylic diffuser plate with high transmittance, by changing the micro structure shape and different arrangement can adjust the diffusion angle of light field and the spatial and energy distribution, to achieve the effect on light diffusing sheet uniformity and light transmittance, thus has caused great concern of researchers.

PMMA diffusion material development process

The development of light diffusion plate material has experienced several stages

1, add the particles with the diffusion effect, improve the light source shielding and get price

2, improve the diffusion effect, improve the appearance of the performance, improve the light transmittance

3, optimized for optical performance, improve the resistance to UV, improve the anti impact performance, improve the efficiency of light, satisfy the requirement of light distribution, high temperature resistant, under the precondition of maintaining high transmittance, enhance product fog value, suitable for close distance irradiation environment.

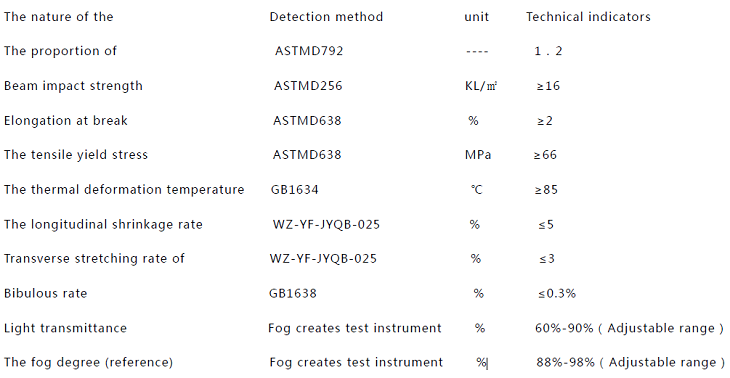

Characteristics and technical index of PMMA diffusion board

1, characteristics

High brightness: under the same penetration rate, the brightness can be higher than the traditional diffusion plate.

Excellent shielding effect: the ability of light source diffusion and uniformity is better, and the effect of the light tube is excellent.

High dimensional stability: low water absorption, good size stability.

Excellent durability in ultraviolet accelerated aging test, not prone to yellowing.

Excellent quality assurance: through the UL-94 and RoHS disable poison test.

2, technical indicators

PMMA diffusion plate application

Acrylic diffuser plate with its obvious performance advantages and is widely used in the lighting field, mainly reflected in the LED flat lamp panel, led downlight, grille lamp, ceiling lamps mask, and advertising light boxes, signs signs and other products.